Produktif Works

There are three major categories of expenses when constructing a new building. One is the cost of the land and infrastructure needed to prepare the site. The second is the cost of the materials used in the building and the logistics to get those materials on site. The third is the cost of the labor required to construct the building. In most cases, to lower the cost in one category, you had to accept higher costs in another category.

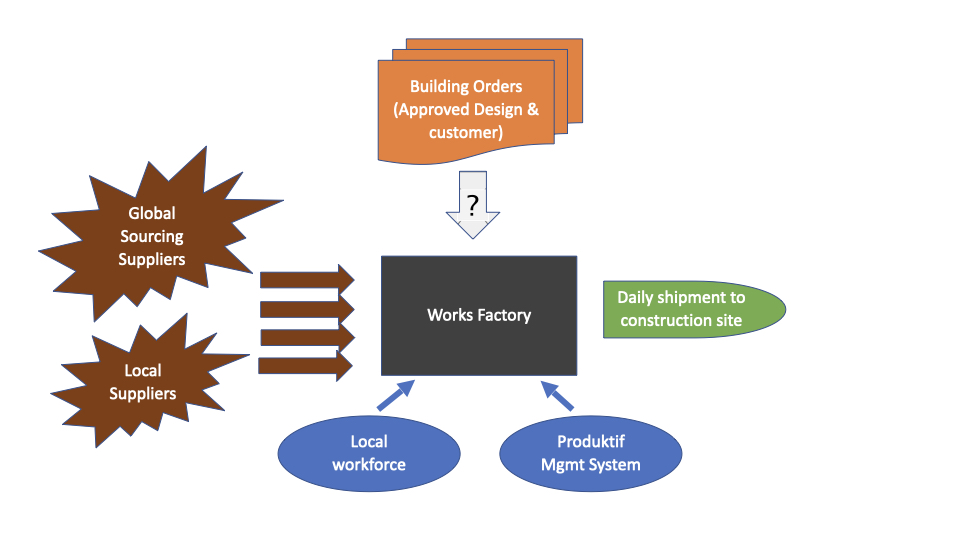

The Produktif Works system addresses all three issues. The Works system is a small, often mobile, factory and logistics center that supports work at construction sites anywhere in the world. It leverages the use of global sources for raw materials and building products to reduce material costs and enable sourcing of environmentally friendly materials and systems. It relies on local manufacturing of custom components and systems in an Industry 4.0 environment that lowers costs and ensures high quality. It facilitates the on-site construction process, providing Just-In-Time delivery of pre-assembled subassemblies to reduce time and waste.

Produktif Works franchises are local small businesses employing workers from the community. A Works operation can provide materials and services to multiple construction sites. The Works operation can support both new construction and the refurbishment and modification to existing buildings. The Works concept is applicable to both residential construction and commercial construction.

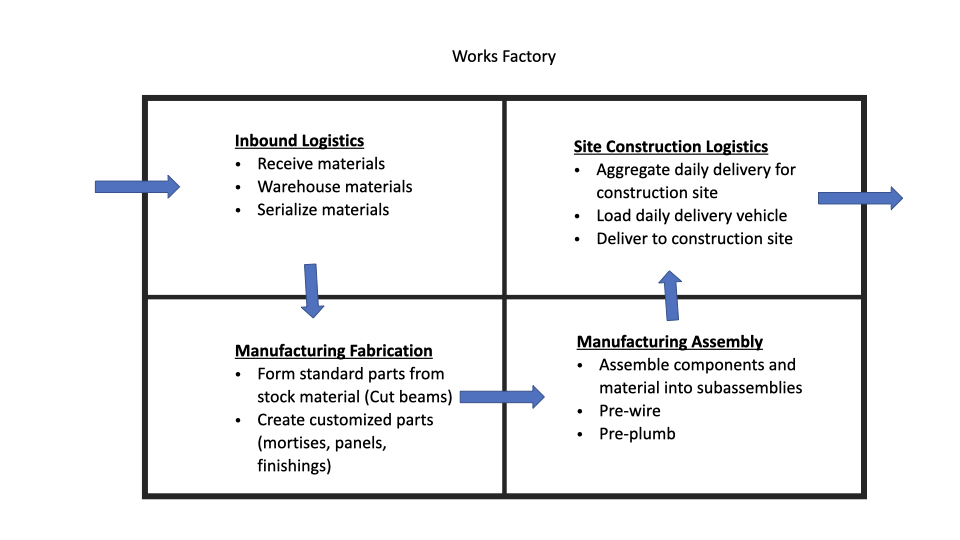

A Works factory has two major section. One is a logistics center. In this portion of the factory, the raw materials and components are received from global suppliers in bulk quantity, often in flat pack pallets. The materials are repackaged into the daily deliver of materials to the construction site based upon the construction build schedule.

The other portion of the Works factory is the fabrication and assembly center. In this portion unique components are fabricated and systems are assembled in a controlled manufacturing environment. Specific configurations of raw materials can be made using CNC systems that precisely meet the requirements of the building under construction. Assembly of building subsystems such as bathrooms, stairways, and utility rooms can be assembled, tested and then transferred to the logistics portion of the building to be delivered to the site and installed.