IMPACT

How will Produktif´s joinery system make a difference?

REUSE and WOOD

We intend to influence how we build tomorrow. Produktif’s joinery system can be reused. Also, we focus on market segments that employ engineered or recycled wood which is an effective strategy to capture atmospheric carbon in biomass:

The construction industry is responsible for more than 35% of the EU's total waste generation (EU “A new Circular Economy Action Plan”, March 2020). The amount of construction waste that gets placed in landfills in Norway is also constantly increasing (SSBs research from 2019). Incremental changes will not solve the challenges in the construction industry, a complete transformation is needed. Early collaboration around a new supply chain in construction is key. Produktif intends to use its joinery system to transform the construction value chain and impact how construction stakeholders work together in the building process. Facilitating the reuse of construction components is an integral part of the EU´s “Green Deal” and “Renovation Wave” Strategy. With clickable connectors the assembly process is easier to plan, can be automated, and will produce less waste and injuries. Produktif´s click/unclick solution brings a focus on process engineering and logistics. This will contribute to making modular construction efficient and more mainstream, saving huge costs and carbon footprint during global transportation.

SCALABLE MODEL

The full impact of the Produktif innovation will be realized through mass production (scale). As more construction stakeholders start adhering to industry 4.0 principles, Produktif addresses scale at three levels:

Scalable geometries: our joinery solution can be scaled from tiny to huge. We are currently working on a medium scale that is a joinery solution suited for constructions up to 7-story buildings. Scalable industrial production: To bring prices down and to eliminate waste and errors, it is key to design joinery solutions for industrial volumes. Scalable and replicable value chain. Produktif’s proposed new value chain can work for a handful of suppliers, builders, and distributors. It can also work for millions of users. Our Product roadmap seeks to include multiple providers of construction solutions.

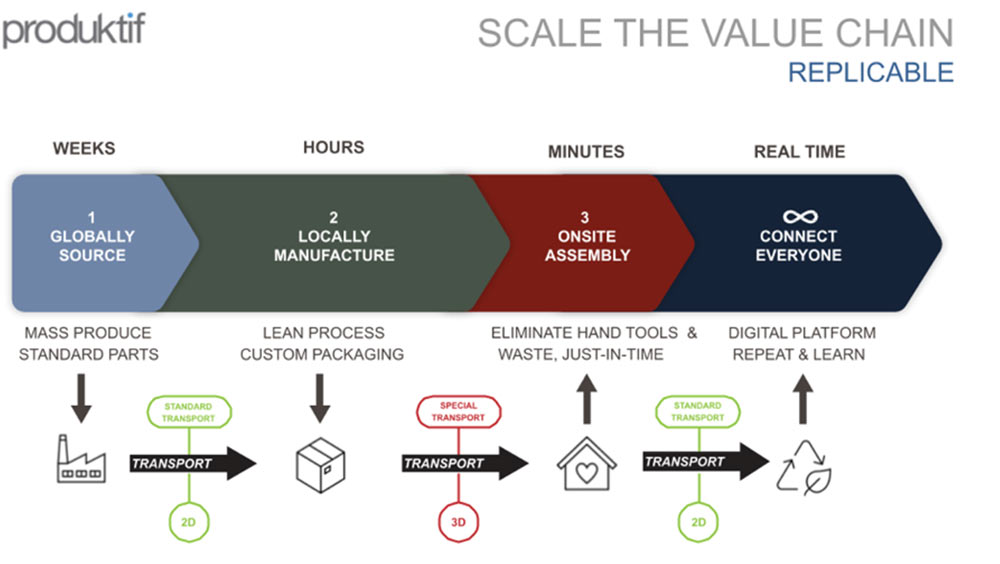

A NEW VALUE CHAIN

The largest impact that Produktif can contribute is by introducing a circular value chain to construction. With our Click/Unclick™ system the construction elements become easy to reuse, the carbon footprint smaller and the construction site safer.

In addition, the new value chain focuses on early collaboration and embedding learning between all stakeholders. By employing the already available digital tools and methods, the construction industry can gain large efficiency improvements through the construction process.

The transformation is driven by digitization and sustainability. Produktif´s new framework for a value chain consists of four phases: Global sourcing, local manufacturing, onsite assembly, and continuous improvement.